CSTJF experts are developing cutting-edge technologies that are fully integrated in the field of drilling. Physics, geomechanics, chemistry, data processing and real-time analysis of parameters recorded downhole, as well as sophisticated control tools, are vital for managing drilling paths that are increasingly complex in conditions that are more and more difficult.

LINKING THE SURFACE TO THE RESERVOIR

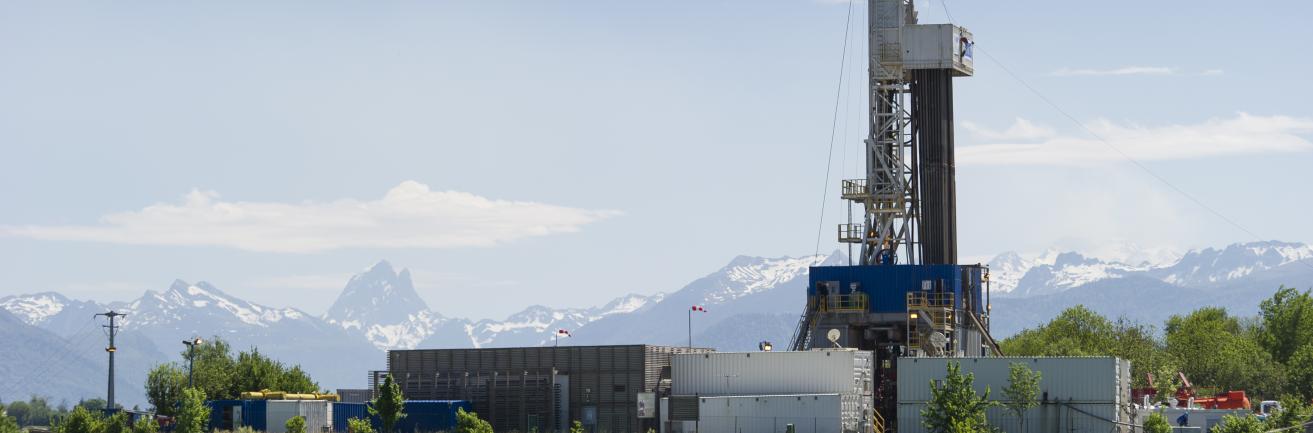

Geological and seismic studies are carried out by the geoscience teams to confirm the hydrocarbon interest of a zone. Following that phase, the drilling & wells teams design a drilling program and then conduct operations in compliance with strict safety and environmental standards.

Their mission also involves analyzing and optimizing techniques and procedures, as well as selecting the equipment best suited to the job.

The initial drilling operations consist in drilling through the Earth's crust to confirm that hydrocarbons are effectively present. This is known as "exploration" drilling.

If oil and gas are present in this first phase, the teams move on to delineation drilling, which "traces" the contour of the field to be drilled. The aim of the preparatory phase is to confirm the results of pre-drilling simulations and interpretations conducted on the field data by exploration teams.

Finally, development drilling is performed to commercially produce the reservoir. The drilling & wells team also draws up drilling, workover or completion programs (well start-up: installation of casing, valves, wellhead, etc.) to ensure that all the "production" wells (that link the hydrocarbon reservoir deep in the ground to the surface installations) are in good working order.

From studies to field operations, from supplier and partner management to contracts management, the role of the drilling & well teams is decisive in the Group's production "chain".

INTERNATIONALLY RENOWNED LABORATORIES AND EXPERTS AT WORK AT THE CSTJF TO MEET UNPRECEDENTED CHALLENGES.

-

The RTSC (Real Time Support Center) Smart Room for drilling operations worldwide.

The RTSC (Real Time Support Center) Smart Room for drilling operations worldwide. -

Laboratory technician mixing cement at the CSTJF mud and cement laboratory.

Laboratory technician mixing cement at the CSTJF mud and cement laboratory. -

Geomechanical engineer preparing a high-pressure/high-temperature test in a specific cell developed at the CSTJF.

Geomechanical engineer preparing a high-pressure/high-temperature test in a specific cell developed at the CSTJF.

High-performance laboratories and experts: a quest for perfection

At the CSTJF, our drilling experts work with integrated high-performance research laboratories specializing in drilling fluids and cements, rock mechanics, near-borehole interfaces and well productivity.

Working closely with operational staff, these teams are able to test, model and validate solutions to improve well integrity and productivity. Their complex modeling allows them to develop custom-designed muds to prevent well fracturing during drilling, thereby ensuring the total integrity of ongoing operations. Using software developed in-house, they can simulate the behavior of wells and cements over their entire lifespan to prevent failure during drilling, completion (all operations prior to an oil well going on production) and production.

We have a Real Time Support Center (RTSC), a smart room based at the CSTJF that provides engineering assistance to affiliates. It can remotely monitor the drilling parameters of wells all over the world, especially the most complex ones, to optimize their performance and further reduce their exposure to major risks. This makes it possible to instantly compare operations performance to standard drilling conditions and lowers monitoring-related costs.

Our drilling expertise covers various sectors up to and including well productivity. We develop advanced stimulation techniques by fracturing, injection or acidification to improve flowrate, fluidity and productivity for all types of formations. With this in mind, our near-borehole laboratory has developed innovative systems and treatments in gravel packing, sand consolidation, scale prevention, etc. These solutions are adapted to reservoir conditions and production objectives and optimize the management of sand penetration through the well/reservoir interface. They use advanced simulation and monitoring software to prevent the formation of sand that can reduce drilling efficiency.

For more information: