Hydrocarbon production is a complex and dynamic process lasting many years, during which huge volumes of fluids, with varying degrees of viscosity and corrosiveness, are set into motion. To respond to the major challenges of the oil & gas sector and to the needs of our partners and stakeholders, our employees are committed every day to producing energy that is ever more affordable, clean, reliable and accessible to as many people as possible.

DEVELOPING INCREASINGLY EFFECTIVE RECOVERY TECHNIQUES

For an oil or gas field to be profitable, it is crucial to maximize its production. We work to optimize our portfolio, while improving the safety of people and facilities and boosting our environmental performance.

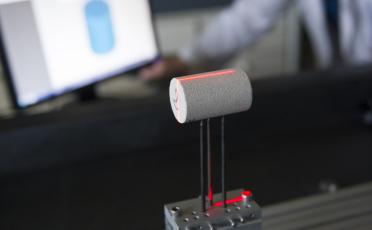

- At the CSTJF in Pau, our experts develop effective gas and hydrocarbon recovery techniques. This involves calculating well trajectories for optimal drainage of the reservoirs and estimating the quantities of oil, gas and water produced by a field in its lifetime.

- Our experts draw on their knowledge of the geology of the area to predict, for each reservoir type, the behavior of the hydrocarbons during production, particularly their ability to flow into the well. In this way, they appraise and neutralize any elements likely to clog or corrode the pipes and thereby hinder production.

Optimizing production and evaluating performance

Some of the major issues for our field operations specialists include anticipating production decline, preventing the alteration of facilities, extending the lifetime of our sites in optimal safety conditions, adapting recovery processes to each reservoir and studying the physico-chemical evolutions of the hydrocarbons produced.

- To enhance the productivity of our fields, the CSTJF has all the necessary resources to improve current techniques and design new ones. And it’s the affiliates of the Company’s Exploration & Production branch that benefit from them.

- Our teams have developed new software programs for the process control systems of oil and gas fields. They systematically optimize production in real time, 24/7, on all wells simultaneously.

- For the Deep Offshore, TotalEnergies creates customized pumps for the development of subsea fields.

Remote monitoring, the business of the CSTFJ experts

These innovations bring with them a new era: one where field performance is monitored remotely, with data accessible in the affiliates and at the CSTJF.

By cross-fertilizing their expertise, the CSTJF engineers contribute to accelerating field development and optimizing productivity.

- The recovery rates of conventional production methods seldom exceed 35%.

Enhanced Oil Recovery can increase this rate by a further 15%. It’s a considerable financial gain for an existing facility. TotalEnergies has a huge degree of expertise in EOR techniques which is based on the use of several types of fluids according to the geological matrices. Analytical chemistry serves to develop additives that are suited to the profile of each reservoir. One of these methods called SWIM (Smart Water Injection Methodology) developed in our laboratories, refines the water composition (salinity, ionic charge, etc.) for each reservoir. At the CSTJF, we also study the possibility of injecting polymers, air, steam, foam or solvents (hydrocarbons and/or carbon dioxide). The aim? To provide innovative solutions for our affiliates to increase the final recovery rate.