Safety, planning, technical modelling and environmental requirements: the Venus project in Namibia encompasses all the constraints associated with drilling in complex conditions. Drilling and Wells Manager Matthieu Pecoits looks back on his career, and explains how teams at the CSTJF in Pau are working to improve industrial performance while reducing environmental impact on this massive project.

After graduating with an engineering degree from the École des Mines d'Albi-Carmaux, Matthieu Pecoits began his career on a VIE (international volunteer) program in Gabon in 2007, working for TotalEnergies. This first position plunged him straight into the world of drilling and offshore operations. Since then, he has worked on various projects, in the middle of the desert in Yemen, on deepwater operations in Nigeria, and then in Uruguay and South Africa, before returning to his native Pau in 2019 to join the CSTJF. In 2023, he began working on the Venus project as drilling and wells manager.

What are your main responsibilities?

My role is to coordinate all studies and modeling to ensure the safety of drilling operations. In practice, this requires an in-depth understanding of the physical and geological conditions under which we operate: pressure, temperature, rock type, risk of erosion or fracture, etc. Based on this data, we select equipment and materials capable of withstanding more than 30 years of use. Drilling is a demanding field, because our production equipment is deep underground, which requires us to model and plan ahead much more than in other industries.

What are the major issues related to well drilling?

The first challenge is safety. In the Oil & Gas sector, there’s no such thing as zero risk. However, we apply the ALARP ("As Low as Reasonably Possible") principle, which consists in minimizing risk to the workers on site, the environment and property. This involves performing in-depth studies on the environmental impact, covering marine ecosystems (fauna, flora, water quality), air quality and climate, as well as the risk of industrial accidents and socio-economic and cultural aspects, which then guide our technical decisions and operational procedures. Keeping to schedule is also important. Drilling is expensive and requires significant human and material resources. The slightest delay can have a major impact on deadlines and budgets. That's why we spend a lot of time modelling different scenarios before validating our decisions.

Why is the Venus project in Namibia so special?

Namibia currently produces less energy than it consumes. With no domestic hydrocarbon production to date, the country imports around 60% of its electricity, mainly from South Africa where power generation relies predominantly on coal. In the longer term, Namibia aims to develop its own energy resources to strengthen its energy sovereignty and reduce its dependence on neighboring countries.

It's a very ambitious project, involving around 40 wells, located 350 km off the coast, at water depth of over 3,000 m. The deeper you drill, the greater the pressure constraints. And we still have to drill down to nearly extra 6,000m for each well to reach the reservoir. We also have to cope with extreme weather conditions, as we're close to the South Atlantic, which is known for its storms. That's why we worked closely with all the experts at the CSTJF in Pau, who provided their input for the overall modeling.

How was this collaborative work organized?

The CSTJF's multidisciplinary teams (geosciences, reservoir engineering, wells and drilling, specialist laboratories) were involved right from the initial conceptual studies, after hydrocarbon was first discovered in 2022. In particular, the CSTJF laboratories work on data analysis and the removal of uncertainties. This work covered all the technical aspects: subsurface characterization (static and dynamic modeling), drilling design and completion, laboratory fluid testing, and production modeling. This combined expertise helped to accelerate the project, so we could move forward with development studies while performing evaluations at the same time, given the extraordinary technical challenges and issues associated with the Venus project.

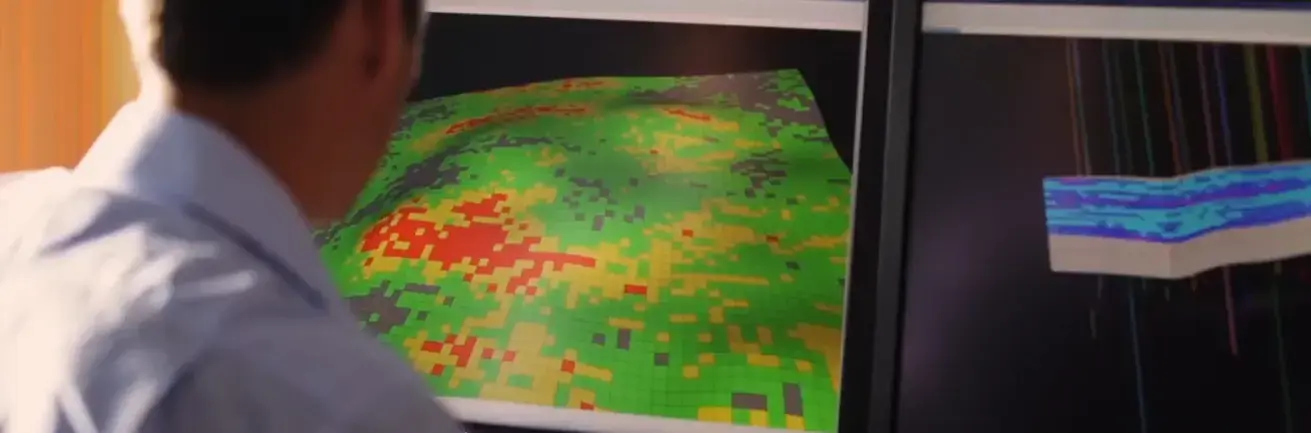

The Geosciences teams at CSTJF created an image of the Venus sand / reservoir deposit and quickly provided the initial data to guide its development. Geologists, geophysicists, sedimentologists and reservoir engineers worked together to interpret the vast array of data collected from the Venus-1X discovery well and the two appraisal wells (Venus-1A in 2023 and Venus-2A in 2024).

The CSTJF's well-drilling department has been closely involved in studies for the Venus project from the outset, in view of its exceptional challenges, such as ultra-deep water and the deep reservoir with low permeability. They are working on three key areas in particular: designing and sizing the well architecture (trajectories and completion) based on comparisons and concept studies, supporting the drilling laboratories to qualify Venus-specific fluids and equipment, and managing well tests and trials to collect critical data. We’ve also developed innovative completion equipment specially for the Venus project, which has been designed and tested to ensure optimum durability against the flow of abrasive sand in producing wells. Modelling of fluid dynamics and laboratory testing were carried out to select the best designs that limit wear while maintaining production performance over the long term.

What specific environmental measures have been taken?

We carried out impact studies at every stage of the project. The Venus strategy is aiming for zero chronic pollution and total control of liquid discharges. The commitments made (no untreated discharges or harmful substances and robust contingency plans) ensure optimal protection of the quality of marine water in the area around the project. As a matter of principle, no persistent or toxic chemicals (e.g. non-biodegradable biocides) will be released into the sea. The products used (corrosion inhibitors, antifoaming agents, etc.) were selected from low impact formulas and are approved by law.

TotalEnergies has made "No Routine Flaring" an imperative for its new projects, and Venus is the perfect example of this. We have opted not to use flaring should the field produce more gas than expected. Flaring is a common practice in the industry, but it has a highly negative impact on the environment. For the Venus project, we will directly and continuously reinject the gas into the reservoir. It's an important decision that will help limit the project's carbon footprint. In addition to avoiding flaring, the Venus teams are working to optimize energy efficiency, by recovering heat to power certain auxiliary systems and improving pump and compressor performance, etc. The result is a highly competitive CO₂ balance. In terms of lifecycle, the project is aligned with TotalEnergies' low-carbon trajectory.

Is this a landmark project in your career?

Venus is certainly a stand-out project! But I could also cite a major project I worked on in South Africa. The weather conditions and sea currents were so challenging that we thought it would be impossible. But we didn't give up! For me, it's a perfect example of the resilience and pioneering spirit at the Company, which is committed to producing oil responsibly to meet today's energy needs, while financing its transition. Today, energy is more sustainable, affordable and reliable, and we’re contributing to this transition by optimizing our operations, as part of a gradual transformation processe.

For the record, I'm a big rugby fan, and even though South Africa was idyllic, I feel right at home in Pau! The Section Paloise rugby team is top of the league and I try to go to the stadium whenever I can to share this passion with my children!

Seeing and understanding the invisible

At what actual depth does a reservoir lie? What are its dimensions? Which sedimentary layers hold the hydrocarbons? What quantity of hydrocarbons do they hold? To answer these questions, the affiliates call on the geosciences business lines. A historical competency at the CSTJF in Pau.

SmartRoom RTSC: Real-time monitoring and assistance for Drilling Operations

All over the world, TotalEnergies directs complex drilling operations to discover and produce new gas and hydrocarbon reservoirs. The Company is currently banking on digital technologies like the Real Time Support Center (RTSC) to optimize the prospection phase and prevent major risks.

Aiming for a bigger buzz and greater heights with the Section Paloise

The club has started the new season as it means to go on - with ambition and intensity. With strategic recruitment, public enthusiasm and a training project backed by TotalEnergies, the Section is aiming to achieve a new milestone.